About Us

A Phelps Family Tradition

Our Story

While we can not be sure when our ancestors started sugaring, we did find an old stone arch in our sugarbush. This likely was built and used by my great grandfather and maybe even his father. My father was Victor Phelps and he boiled off and on over the years along with helping my uncles in Troupsburg, NY. Dad started boiling over a barrel stove with a flat pan in the early eighties. This was the beginning of his annual commitment aka addiction to sugar making.

Growing the Operation

After a few years of working the flat pan dad purchased a 2 x 6 raised flue evaporator making the process easier and probably more addicting. As his operation slowly grew, dad would make 20-30 gallons per year. Most of the syrup made in the days of old was for family consumption and to give away to family, friends, neighbors and co-workers.

Increasing the Production

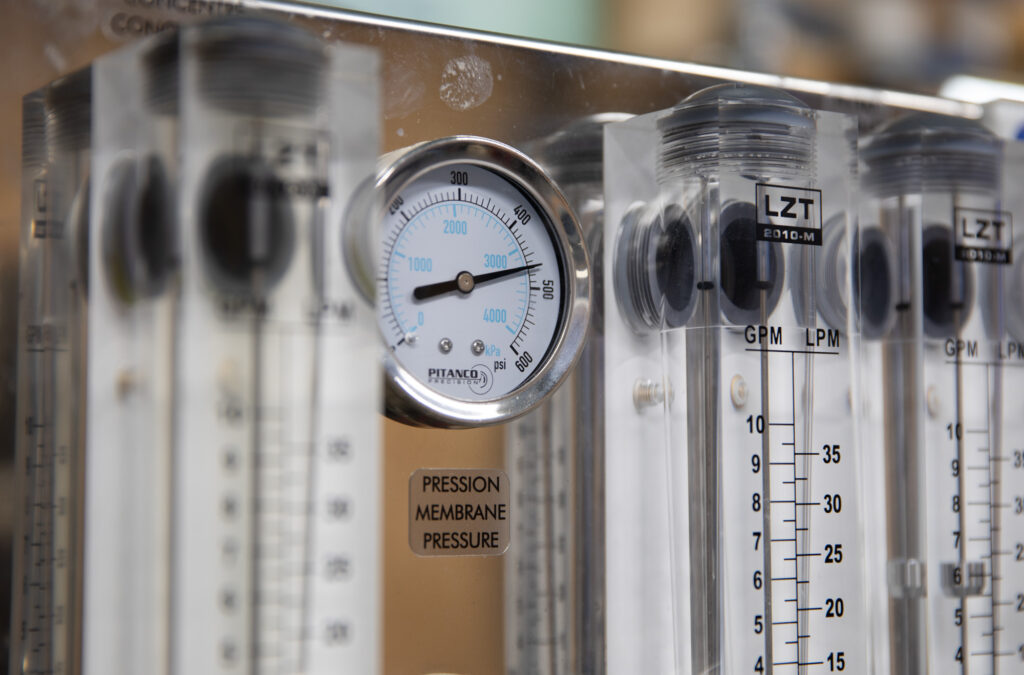

I purchased the land and sugaring equipment in 2015 before dad died and our first year of production was the 2016 season. We formally became Phelps Family Maple and made 15 gallons of syrup that year. We made a lot of mistakes but learned from our mistakes and continued to make improvements and increase the size of our operation. With the addition of taps, I soon realized that adding reverse osmosis was my only option to not having to stay up all night boiling. We purchased a 200 gallon per hour RO and a year or two later modified it to process 300 gallons of sap per hour. By this time, we were making about 100 gallons of syrup each year.

Keep the Flavor

We committed to increasing our tap count and secured a lease nearby on the Ding Dang Road. With the anticipated sap increase, that meant increasing production capacity so we purchased a larger evaporator the summer of 2020. The new evaporator is a 2 1/2 x 10 foot CDL Venturi. It was important to me to keep the traditional wood fire as I believe that process improves the flavor of the syrup we produce.

The Truth is in the Bottle

As we continued to expand and our tap count grew, we added a larger 1200 gallon/hour RO and a 2,000-gallon tanker to transport our sap. We are now making about 400 gallons of pure wood fired maple syrup a year with expectations of continued expansion. This syrup is sold as pure maple syrup, bourbon barrel aged maple syrup and cinnamon infused maple syrup. Additionally, our syrup is transformed into maple cream, maple candy, maple sugar, and even maple cotton candy right here on the farm.

The Legacy Lives On

This process is only possible with the assistance of a dedicated team that includes my wife Carol and Katy Kriner who help with sales and marketing and my son Ben and brother Steve who assist with all aspects of the operation including building lines, collecting, boiling, bottling and sales. We also have multiple friends who assist with tapping each year. Together we are Phelps Family Maple.

Take a peek behind the scenes.

Browse our photo gallery to get a glimpse of how we make our products